HYBRIT:s Hydrogen storage won Ny Tekniks Grand Prize for Engineering 2025 in Sustainability

Marie Anheden, Vattenfall, Project Manager for the Hydrogen Storage Project and Gunilla Hyllander, General Manager at Hybrit Development AB (Photographer: Markus Fischer, Vattenfall)

Fossil-free hydrogen storage in lined rock caverns ready for industralization and now the hydrogen storage project has won the Grand Prize for Engineering 2025 in Sustainability, a prestigious award awarded by the magazine Ny Teknik to pioneer sustainability solutions.

The technology to make industrial hydrogen production and usage more flexible and profitable for those that invest in fossil-free steel production with hydrogen is now available. Vattenfall, SSAB and LKAB started HYBRIT in 2016.

– The production of fossil-free hydrogen is the key to replacing the traditional blast furnace process for steelmaking. Today, the steel industry accounts for a large share of the industry’s carbon dioxide emissions, corresponding to 7 percent of global and over 10 percent of Swedish emissions. The blast furnaces are the largest single source of emissions. Hydrogen production requires a lot of electricity, but hydrogen storage is a solution to meeting the challenges ahead, where varying demand for and supply of electricity means that the price of electricity varies. This can also reduce the variable operating costs of hydrogen production by up to 40 per cent. HYBRIT is a success, and it is very pleasing that it is being recognized in this way, says Marie Anheden at Vattenfall, who was project manager for the Hybrit pilot project that received the award.

– When the HYBRIT initiative was launched in 2016 by SSAB, LKAB and Vattenfall, the aim was to revolutionize the steel industry by developing the world’s first fossil-free, ore-based iron- and steelmaking using fossil-free electricity and hydrogen gas. The fact that HYBRIT now shows that hydrogen storage works in the value chain is a crucial piece of the puzzle in place – and truly something to celebrate, says Eva Petursson, VP Research and Innovation, SSAB.

– We are very happy about this recognition and, above all, about the journey we have made together on the HYBRIT project. Hydrogen is one of several important parts of LKAB’s future strategy and journey towards carbon dioxide-free processes. The successful results from the pilot give us good conditions when we review the needs and opportunities for storage in conjunction with our planned sponge iron production facilities, says Jenny Greberg, Vice President of Technology at LKAB.

Design and construction of the pilot storage

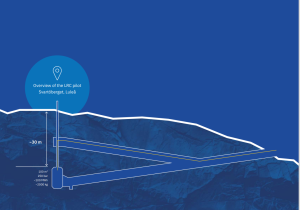

HYBRIT has now developed the technology for hydrogen storage in rock caverns through a project carried out during the period 2019-2024. The project entailed the design, construction, and operation of a pilot-scale hydrogen storage facility with a capacity of 100 cubic meters, situated 30 meters below the ground surface in Svartöberget, Luleå, within LKAB’s industrial area. The maximum pressure level is 250 bar in the storage, and the maximum amount of hydrogen stored is about 2 tonnes. The hydrogen storage will remain in operation until at least 2026.

The basic concept of LRC storage (Lined Rock Cavern) has already been demonstrated on an industrial scale for natural gas in Skallen, outside Halmstad. However, the concept needs to be adapted for hydrogen storage, especially in terms of material selection. To cope with the fluctuations in the electricity market, it is expected that a commercial hydrogen storage facility needs to be filled and emptied with higher frequency and speed compared to a natural gas LRC. This also implies different requirements for the design and operation of the facility.

LRC technology is well suited for Swedish conditions where we have encountered high-strength crystalline rock, but not geological conditions for storage in natural geological formations such as salt domes or aquifers.

A LRC storage consists of an excavated rock cavity, shaped as a vertical cylinder with a rounded top and bottom. The rock cavern is fitted with a gas-tight liner consisting of: a steel liner (toward the gas), a force-transmitting reinforced concrete layer (between steel liner and rock), a sliding layer (between steel lining and concrete to reduce friction) The forces from the high storage pressure are transferred via the liner to the rock mass, which has the strength to withstand very high loads, ca 200-300 bar. At the same time as the storage can be placed at reasonable depths. The liner (LRC) ensures that the storage is gas tight.

The forces from the high storage pressure are transferred via the liner to the rock mass, which has the strength to withstand very high loads. Around the facility, there is a drainage system that removes water during the construction phase and monitors gas tightness during operation.

Basic overview of the installation of the pilot storage in Svartöberget.

– The choice of material for the storage’s steel lining has been one of main issues during the design phase. The material is resistant to the effects of hydrogen on the material and can withstand the cyclical load of frequent emptying and filling of the storage. No leakage of hydrogen gas from the sealing layer of the storage facility has been detected, says Marie Anheden.

Results in brief:

- Over more than two years of operation with hydrogen, the safety, functionality and performance of the plant have been successfully demonstrated.

- Approximately 4 900 hours of hydrogen operation with 95% availability have been achieved.

- The maximum pressure level is 250 bar (corresponding to 2 500 m water depth).

- The maximum amount of hydrogen stored is about 2 tonnes.

- The pilot storage facility has also been subjected to accelerated mechanical tests through frequent variations between high and low storage pressure. The tests performed correspond to the same mechanical load as during an expected lifetime of at least 50 years of a commercial large-scale storage facility.

- The storage can be emptied and filled at the frequency and rate required to match the fluctuations in the electricity system.

Hydrogen storage supports the transition to a fossil-free society

There are several benefits of large-scale hydrogen storage, both for industrial operations and for the electricity grid in general. The main advantage is that hydrogen storage supports the transition to a fossil-free society, by:

- Lowering the variable operating cost of hydrogen production

By taking advantage of variations in electricity prices, hydrogen storage allows electricity to be stored as hydrogen when electricity prices are lower – and the stored hydrogen to be used in the industrial process when electricity prices are higher. Savings of up 40% of variable operating costs are possible through large-scale hydrogen storage. Simulations carried out on scenarios for the future Swedish electricity market conducted by Vattenfall show that further savings can be made by participating in additional markets such as the intraday market.

- Creating flexibility

A hydrogen storage facility creates flexibility for industrial operations that use hydrogen. It also creates resilience against disruptions in hydrogen production, as there is always hydrogen available in the storage to supply the production.

- Stabilizing the electricity grid

Large-scale hydrogen storage stabilizes the electricity grid, by balancing electricity both when supply is good and when demand is high. This balancing evens out electricity price variations.

- Stabilizing fluctuations in the electricity market

Which would benefit investments in new electricity production from all fossil-free power sources – more variations from weather-dependent electricity production can be balanced in the electricity system.

– The pilot project has been highly successful and has given us the results we hoped for. We have shown that it is possible to use this technology to increase the flexibility of the electricity system and that it is a safe design that lasts over time. Hydrogen gas storage is an important piece of the puzzle to electrify industrial processes while increasing the amount of weather-dependent power. With the results and experiences gained from the pilot project, the technology is now ready to be scaled up, says Mikael Nordlander, Director, Industry Decarbonisation at Vattenfall’s Industrial Partnerships.

HYBRIT’s pilot project for hydrogen gas storage has now been completed and reported to the Swedish Energy Agency. The results show that it is technically possible to store fossil-free hydrogen gas for producing fossil-free iron and steel on an industrial scale.

The Swedish Energy Agency has co-financed 22 per cent of the hydrogen storage project, with the remainder having been financed by the owner companies.

HYBRIT has extended the pilot project for storage of fossil-free hydrogen gas until 2026 to be able to carry out additional tests to further improve the conditions for enabling the design of commercial hydrogen storage.

Facts:

- Blast furnaces process accounts for approximately 85-90% of the total carbon dioxide emissions in ore-based steel production.

- HYBRIT is the world’s first fossil-free steel production using fossil-free pellets, electricity and hydrogen.

- During the period 2019-2024 the project entailed the design, construction, and operation of a pilot-scale hydrogen storage facility with a capacity of 100 cubic meters, the storage is in operation.

- HYBRIT’s pilot storage of 100 m3 and has been tested in real time against the electricity market.

- In a future Future commercial scale it is about ∽ 50,000 to100,000 m3

- The pilot storage has been in intermittent operation with hydrogen since 2022, in campaigns of 3 to 6 weeks. Approximately 4 900 hours of hydrogen operation with 95% availability have been achieved.

- Tests at the pilot plant in Luleå have demonstrated that large-scale storage of hydrogen using LRC technology is technically feasible. And hydrogen storage works in Hybrit’s value chain to support a large-scale hydrogen user, in this case a direct reduction plant in Luleå.

- Optimised operation of the storage facility has been done in real time both against the spot price and intraday market. Savings of 26-31 per cent of variable operating costs have been demonstrated in practice. Simulations of future scenarios for the Swedish electricity market indicate that savings of about 25-40 per cent of variable operating costs could probably be reached when the first commercial plants are commissioned.