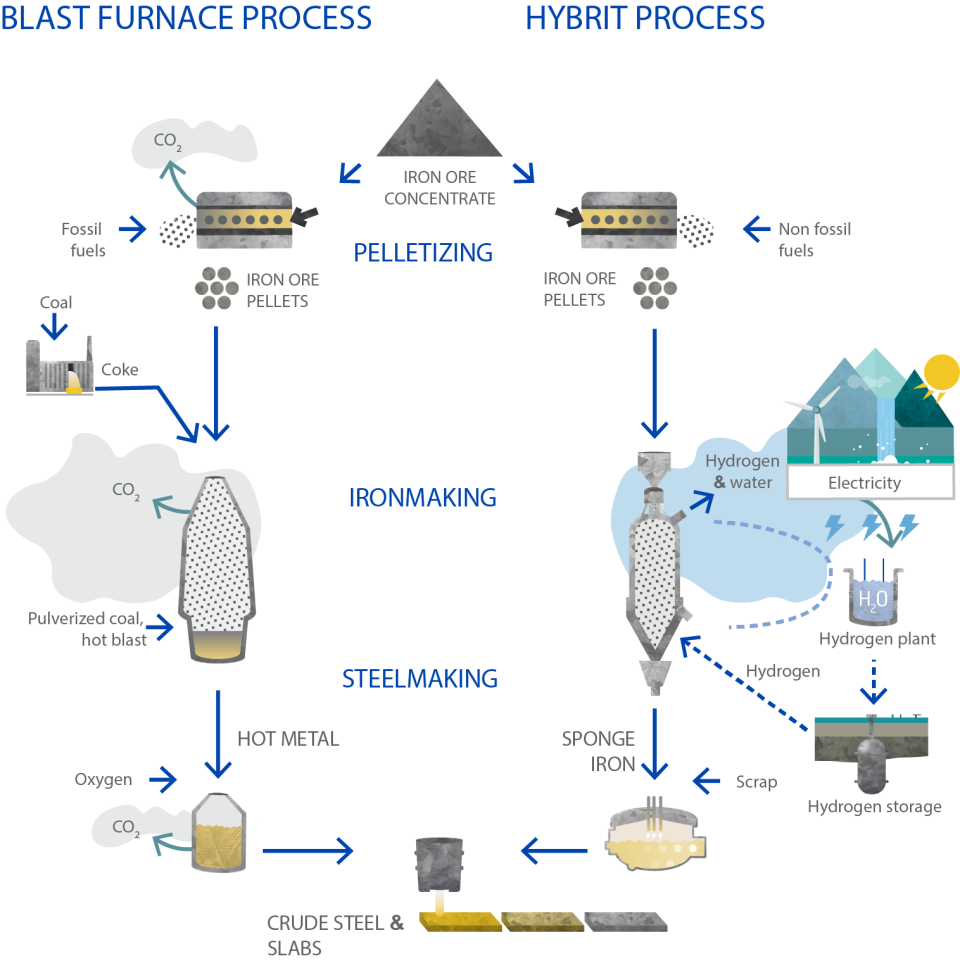

Steel can be manufactured by recycling or by using iron ore as raw material. In the HYBRIT process the raw material is iron ore, in the form of iron ore pellets. The ore, which is mined in LKAB’s mines for further processing in SSAB’s steelwork, is enriched and sintered into iron ore pellets. Today, the sintering is done with fossil fuels but, in the framework for the HYBRIT initiative, biofuels have been used in LKAB’s ore processing plant instead.

The iron ore pellets are currently shipped to SSAB’s plants, in Luleå, Oxelösund in Sweden and Brahestad in Finland, for further processing. The iron ore is an oxide in which the iron is combined with oxygen and, to produce steel, the oxygen must be removed from the ore. Today, the oxygen is removed (reduced) from the iron ore using carbon and coke in SSAB’s blast furnaces. The raw iron that is tapped from the blast furnace is liquid and moves on in that form through the steel manufacturing process until, as raw steel, it is poured out as slabs.

The HYBRIT process means that the oxygen is removed instead from the iron ore using fossil-free hydrogen, this takes place in a reduction shaft. The result is sponge iron (direct reduced iron), which is a solid product with the same shape as the iron ore pellets that were fed into the reduction shaft. In the HYBRIT process, the sponge iron is then smelted in an Electric Arc Furnace (EAF). The process is made fossil-free by using fossil-free electricity and by increasing the use of non-fossil additives instead of fossil carbon.

In the HYBRIT process, fossil-free hydrogen is central. This is produced by the electrolysis of water and it is used in the direct reduction to remove the oxygen from the iron ore pellets. The electrolysis takes place using fossil-free electricity. The hydrogen that will be used in the process is produced next to the direct reduction plant and can be used directly in the process.

The fossil-free value chain of the future also includes hydrogen storage. Storing hydrogen gives an opportunity to stabilize the energy system by producing excess hydrogen when there is plenty of electricity, for example when it is windy, and using the stored hydrogen when the electrical system is under strain. To ensure uninterrupted iron and steel production, the ability to store fossil-free hydrogen under efficient and safe conditions is important, all in accordance with society and the authorities’ requirements.